Molding line made ductile iron mechanical adapter

Molding line made ductile iron mechanical adapter Molding line produces gray iron converters

Molding line produces gray iron converters Modeling line production of high quality ductile iron photovoltaic base station accessories 2

Modeling line production of high quality ductile iron photovoltaic base station accessories 2 Modeling line production of high quality ductile iron photovoltaic base station accessories 1

Modeling line production of high quality ductile iron photovoltaic base station accessories 1 Precision cast alloy steel machine parts dipped in red paint

Precision cast alloy steel machine parts dipped in red paint Black spray precision cast carbon steel machinery parts

Black spray precision cast carbon steel machinery parts- All new products

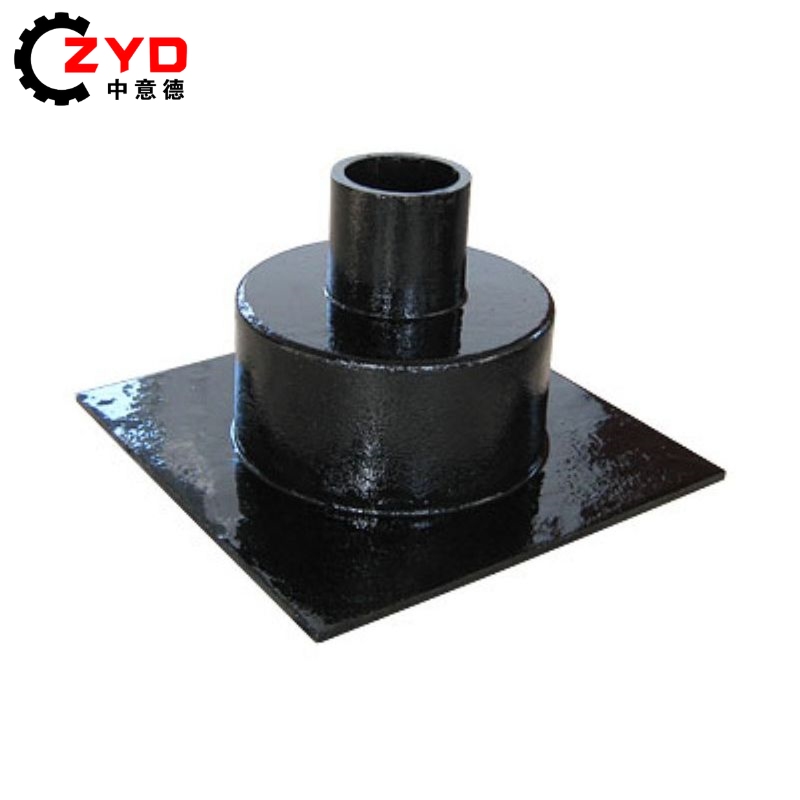

Molding line cast HT250 gray iron building accessories

This product is suitable for building structures, bridges, mechanical equipment and other fields, and is a core component of construction and engineering equipment.

Product Description

ZYD is an OEM factory with more than 20 years of casting processing and production experience. We have independent mold design and mold making, rich casting technology, precise processing equipment, high-quality packaging and customer-satisfying quality and service. We mainly operate in the European and North American markets. In the long-term cooperation with customers, we have gained unanimous praise from customers for our products.

1. High-quality HT250 gray iron building accessories product introduction

HT250 gray iron is a high-strength gray cast iron material with excellent mechanical properties, wear resistance and shock absorption performance, and is widely used in the fields of construction and machinery manufacturing. The HT250 gray iron building accessories produced by the molding line casting process have high precision, high stability and long service life. This product is suitable for building structures, bridges, mechanical equipment and other fields, and is a core component of construction and engineering equipment.

2. Product advantages

High strength and rigidity

HT250 gray iron can withstand high loads and complex stresses, ensuring the stability and reliability of the operation of building accessories.

Excellent shock absorption performance

Effectively absorb vibration, reduce vibration and noise in building structures, and improve the stability of equipment operation.

High precision and high stability

The casting process of the molding line ensures high dimensional accuracy and good surface quality of the product, meeting the high requirements of the building structure.

Long service life

High wear resistance and durability significantly extend the service life of building accessories and reduce maintenance costs.

Economical and practical

HT250 gray iron has low cost and high cost performance, suitable for large-scale production.

3. Application areas

Building structure

Applicable to supports, connectors, etc. in building structures, and can withstand high loads and complex stresses.

Bridge engineering

Applicable to connectors, supports, etc. in bridge engineering, with good wear resistance and corrosion resistance.

Mechanical equipment

Applicable to bases, brackets, etc. in mechanical equipment, with good shock absorption performance and stability.

Other engineering equipment

Such as lifting equipment, transportation equipment, etc., suitable for parts that require high precision and high stability.

In the construction industry, the quality of accessories directly determines the stability, safety and durability of the building structure. As a professional high-quality OEM building accessories production factory, we provide customers with high-precision and high-reliability building accessories solutions with exquisite craftsmanship, advanced technology and strict quality standards, helping construction projects to advance efficiently and build a better space for the future.

1. Professional OEM service, tailor-made

We have rich OEM production experience and can provide personalized design and manufacturing services according to customer needs. Whether it is drawing customization, material selection, or process optimization, we can accurately meet your needs and ensure that the accessories are perfectly matched with your equipment.

2. Advanced technology, quality assurance

Adopting advanced casting, heat treatment and machining technology, from mold design, production casting, heat treatment, precision machining, surface treatment, the entire production process combined with a strict quality control system, each product undergoes a strict testing process to ensure that the quality of each product sent to customers is reliable.

3. Diversified material selection to meet different needs

We provide a variety of material options, including gray iron, ductile iron, carbon steel, alloy steel, stainless steel, cast aluminum, etc. Including various special materials of cast iron and cast steel, such as heat-resistant alloy ductile iron, austempered ductile iron, silicon solid molten ductile iron, high chromium steel, high manganese steel, etc. Provide a variety of material options according to customer needs.

4. Green production, practicing sustainable development

We are committed to green casting technology, reducing energy consumption and environmental pollution in the production process, and contributing to sustainable agriculture.

5. Efficient production and fast delivery

Relying on modern production lines and efficient management systems, we can achieve rapid response and on-time delivery, helping customers shorten production cycles and improve market competitiveness.

6. Full service, worry-free cooperation

From demand communication, sample production to mass production and after-sales support, we provide one-stop service throughout the process to ensure that customers can feel professional and considerate in every link.

Choose us, choose professionalism and trust!

Whether it is large-scale mass production or small-batch customization needs, we will become your trusted OEM partner with exquisite craftsmanship, reliable quality and efficient service.

English

English