ABOUT US

Gaomi Zhongyi De Machinery Manufacturing Co., LTD., founded in 2001, is located in Hujiazhuang Industrial Park, Gaomi City, Shandong Province, located in the core area of Shandong Peninsula economic circle, only one hour's drive from Qingdao port and Jiaodong International Airport, with convenient land and sea transportation.

The company has always adhered to the management philosophy of "people-oriented, treating people with sincerity, winning with quality, pioneering and innovative". After nearly 30 years of steady development, the plant covers an area of nearly 50,000 square meters, the annual output of more than 10,000 tons, including product design, mold processing, casting, processing, testing, surface treatment, assembly and packaging integration, to meet the expectations and needs of every customer. The company has more than 180 employees, including many professional engineering and technical personnel, and senior experts for enterprise consultants, involved in process design and product development.

The company pays attention to the introduction of the world's advanced production technology and management experience, in May 2010 with the German Heinrich-Wilhelm Rodenbostel established Gai Zhongyi German Precision casting Co., LTD., committed to alloy steel parts precision casting and processing. With a good casting and processing foundation, the products are exported to Germany, Britain, France, Italy, the United States, Canada, Japan, Malaysia, Saudi Arabia and other overseas markets.

The company is committed to gray cast iron, alloy gray cast iron, ductile cast iron, Aube ductile cast iron (ADI, CADI), heat resistant alloy, ductile cast iron, silicon solid melting ductile cast iron, stainless steel, alloy steel, carbon steel, cast aluminum and other parts manufacturing and processing and actively expand the product categories, Nearly three thousand varieties are widely used in agricultural machinery, trucks, machine tools, water pipes, hydraulics, automotive engine exhaust pipes and pump devices and other fields.

The company has Japanese Tokyu automatic clay sand production line 3 (including size 610mm*530mm, 600mm*700mm and 800mm*900mm), resin sand molding line, coated shell production line, automatic wax shooting machine, medium frequency induction furnace, vacuum heat treatment equipment, South Korea HYUNDAI-WIA Five axis machining center, Taiwan YOU JI Turning Machining Center, BYJC four-axis Horizontal Machining Center, Taiwan Vision Wide Machining Center, fine carving machine, four-axis vertical machining center, three-axis vertical machining center, CNC lathe, double-sided dynamic balance experimental machine, ultrasonic cleaning machine, automatic spray molding line and other international advanced level of casting production equipment and machining equipment, Formed a professional, digital, intelligent production line in line with international standards.

The company adheres to scientific verification, standardized measurement, It has successively introduced melting data acquisition and analysis system, pre-furnace carbon and sulfur rapid analyzer, direct reading spectrometer, metallographic analysis microscope, metal testing machine, Boule and Low hardness tester, impact testing machine, magnetic particle flaw detection machine, ultrasonic detector, Solidcast casting simulation software, AtlaScan Ultra 3D scanners, Hexagon Cambridge three-dimensional coordinatograph, Aolong XXYG-4510 fixed X-ray flaw detector provide a solid hardware guarantee for product quality and R & D quality control. The company is currently expanding and upgrading equipment, with a new thermostatic machining shop to be put into use in June 2025, and the acquisition of new three-position coordinators and precision machining equipment to meet customers' increasingly precise machining requirements.

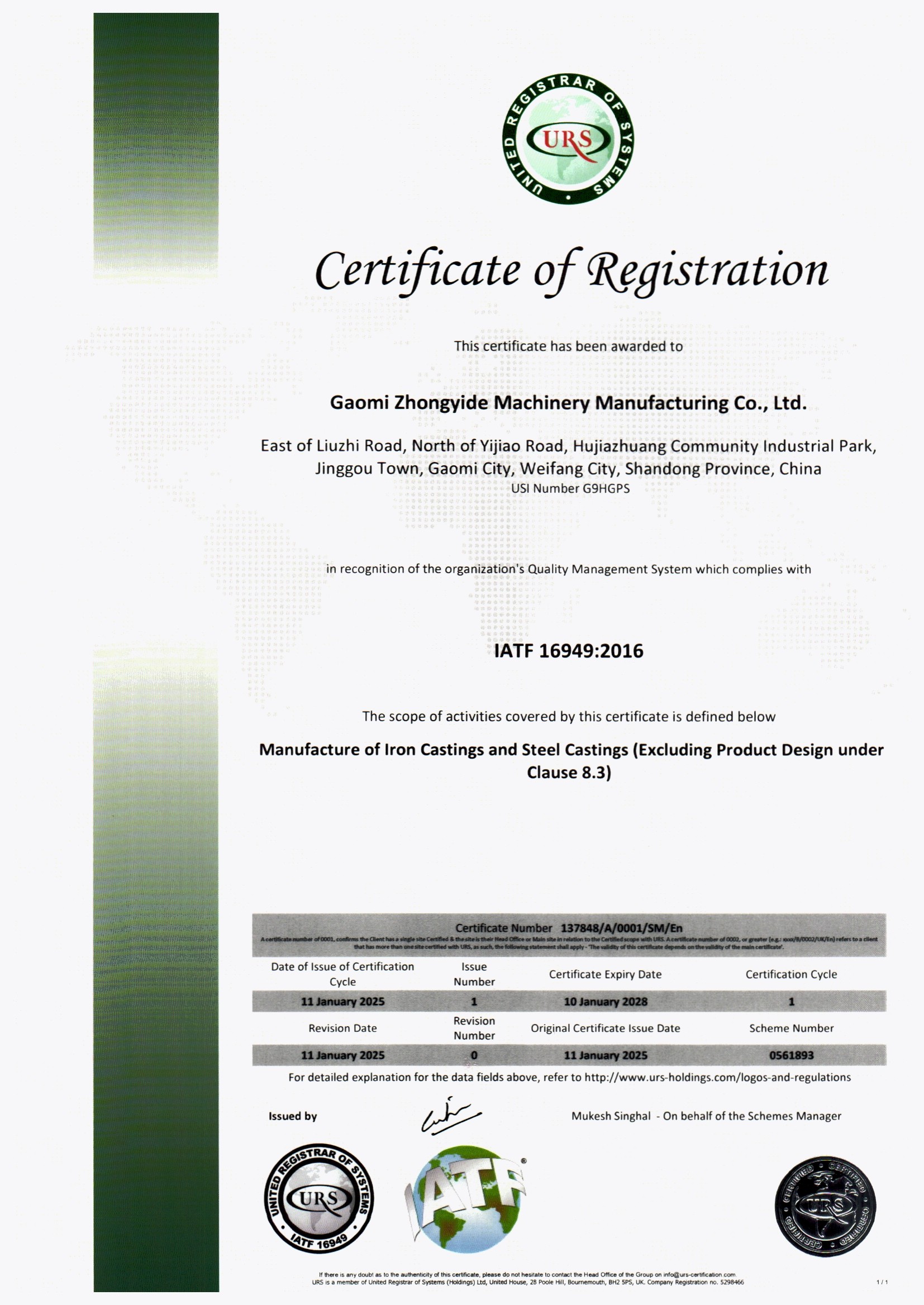

The company has passed IATF16949, ISO 9001 quality management, ISO 14001 environmental management, ISO 18001 Occupational health and safety, foundry standard Enterprise, three-level safety standardization, CLAAS-VDA6.3 and other system certifications, and uses the network big data platform to supervise and manage the production process. Ensure that the product production process is humanized, standardized and standardized.

Adhering to the principle of "scientific and technological innovation is the first productive force", the company constantly innovates and improves the existing production technology, develops new materials and purchases advanced equipment. The company plans to put into use the fully automatic casting system in June 2025 and connect it to the company's digital management system. In December of the same year, the company will introduce a fully automatic silica sol process production line, which is used to produce more high-quality precision products, upgrade the existing precision manufacturing technology, and expand the materials that can be produced.

English

English