Quality Equipment

The company consistently upholds a scientific and rigorous approach, adhering to standardized measurement protocols, and has continuously introduced a system of internationally advanced R&D and testing equipment.

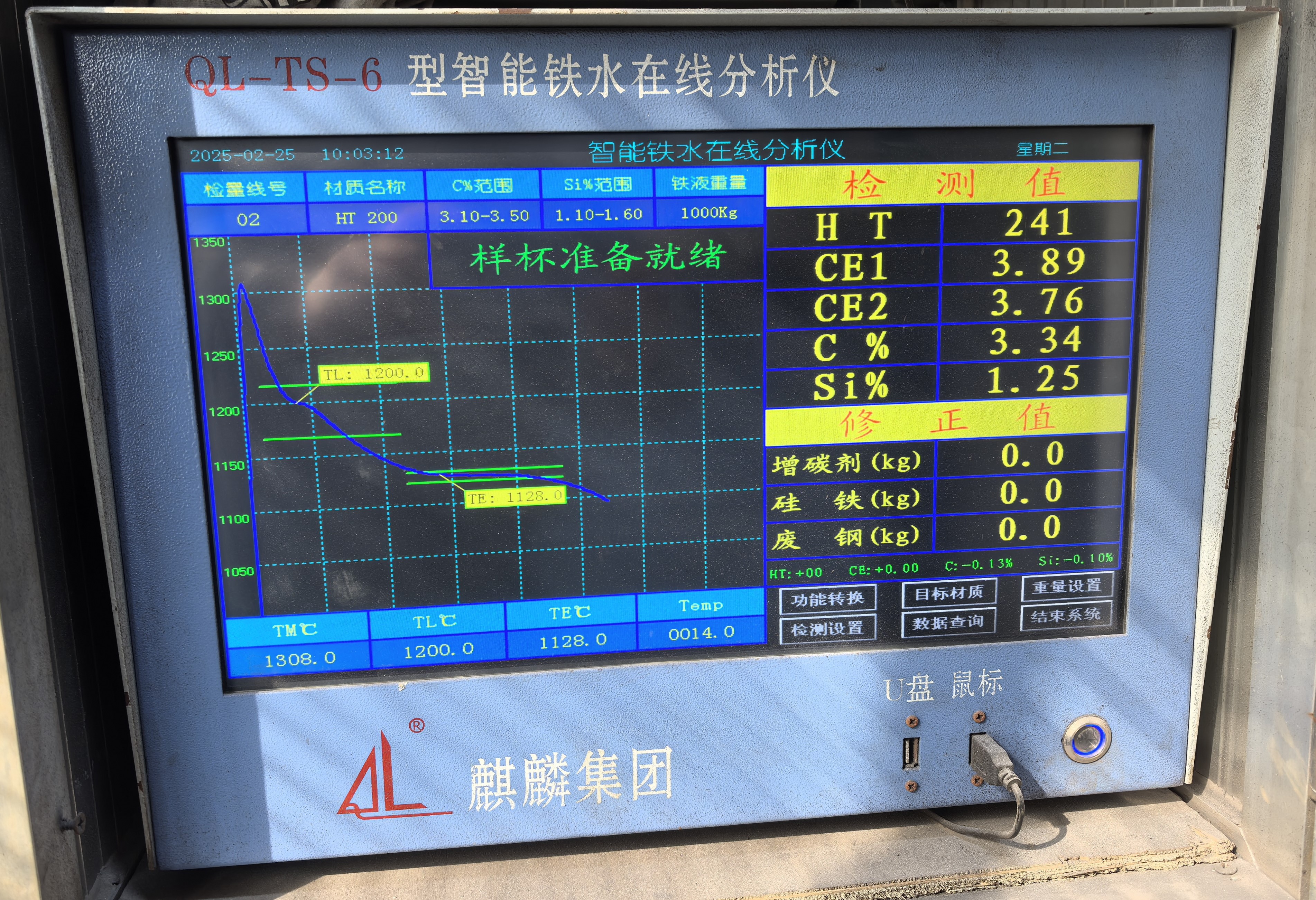

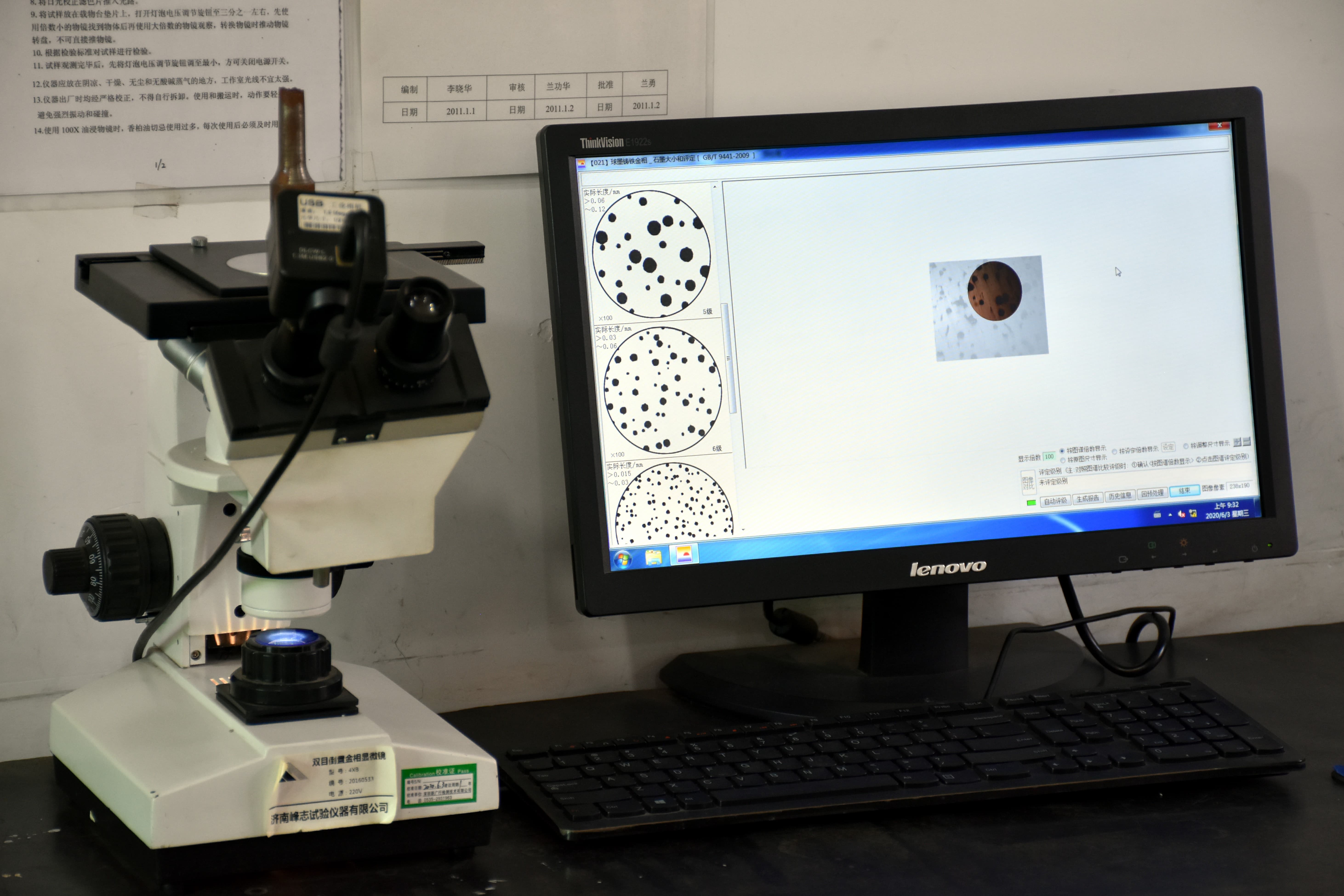

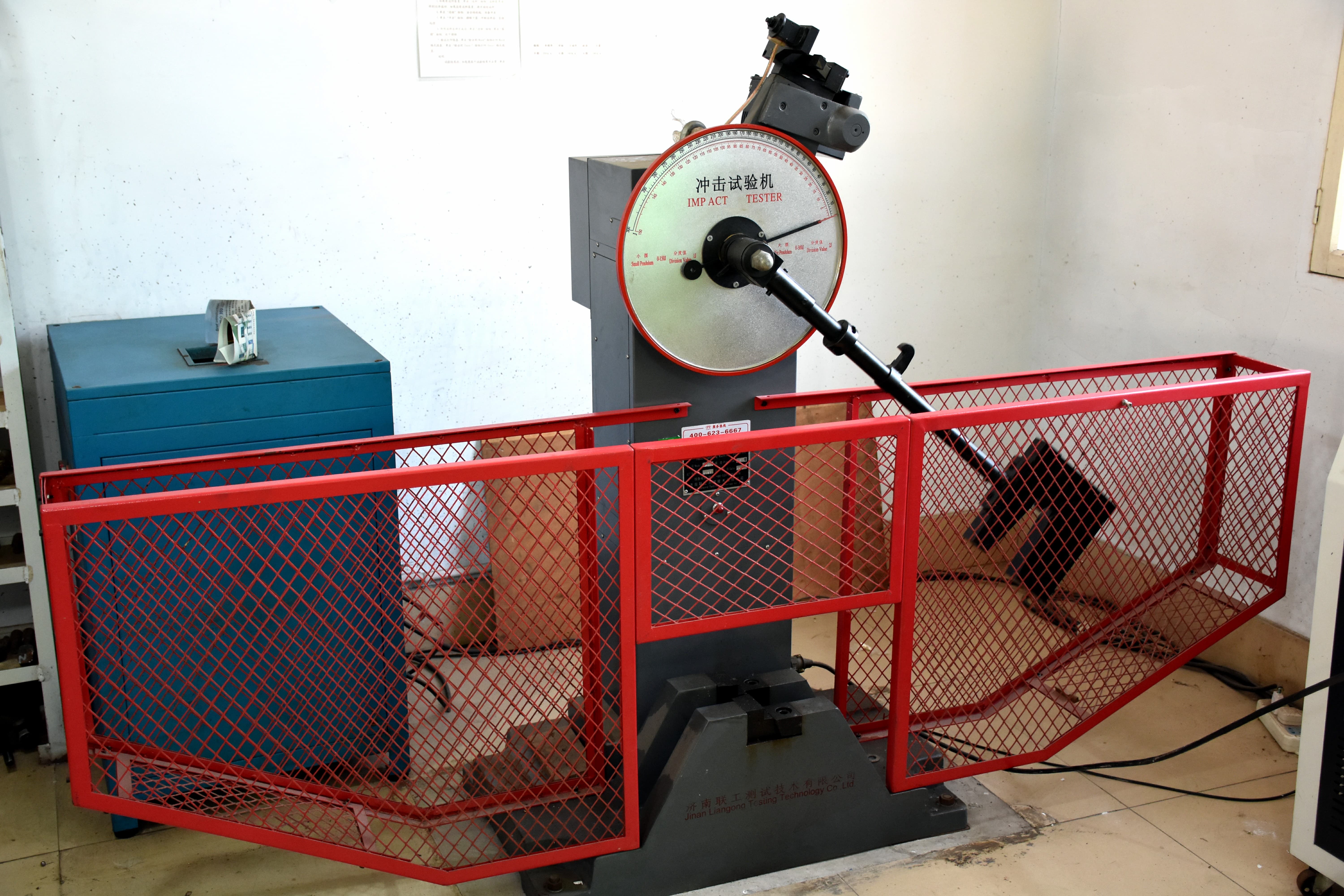

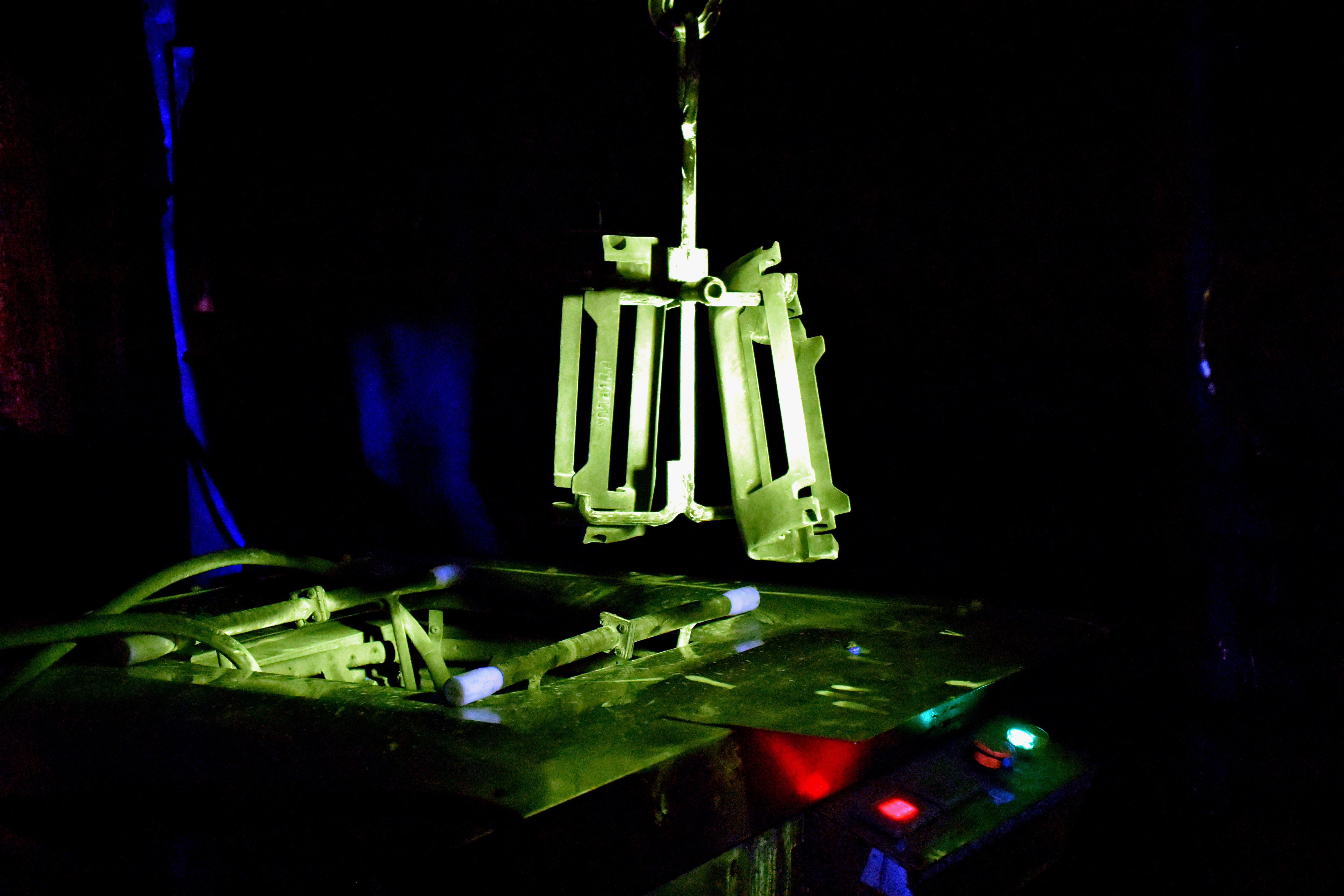

In the field of material analysis, the company is equipped with high-precision optical emission spectrometers, rapid carbon-sulfur analyzers for molten metal testing, and metallographic microscopes. For mechanical property testing, it utilizes computer-controlled electronic universal testing machines, fully automated impact testers, and Brinell/Rockwell hardness testers. In nondestructive testing, the company has established a comprehensive inspection system, including ultrasonic flaw detectors, magnetic particle inspection equipment, and a 450KV X-ray inspection chamber.

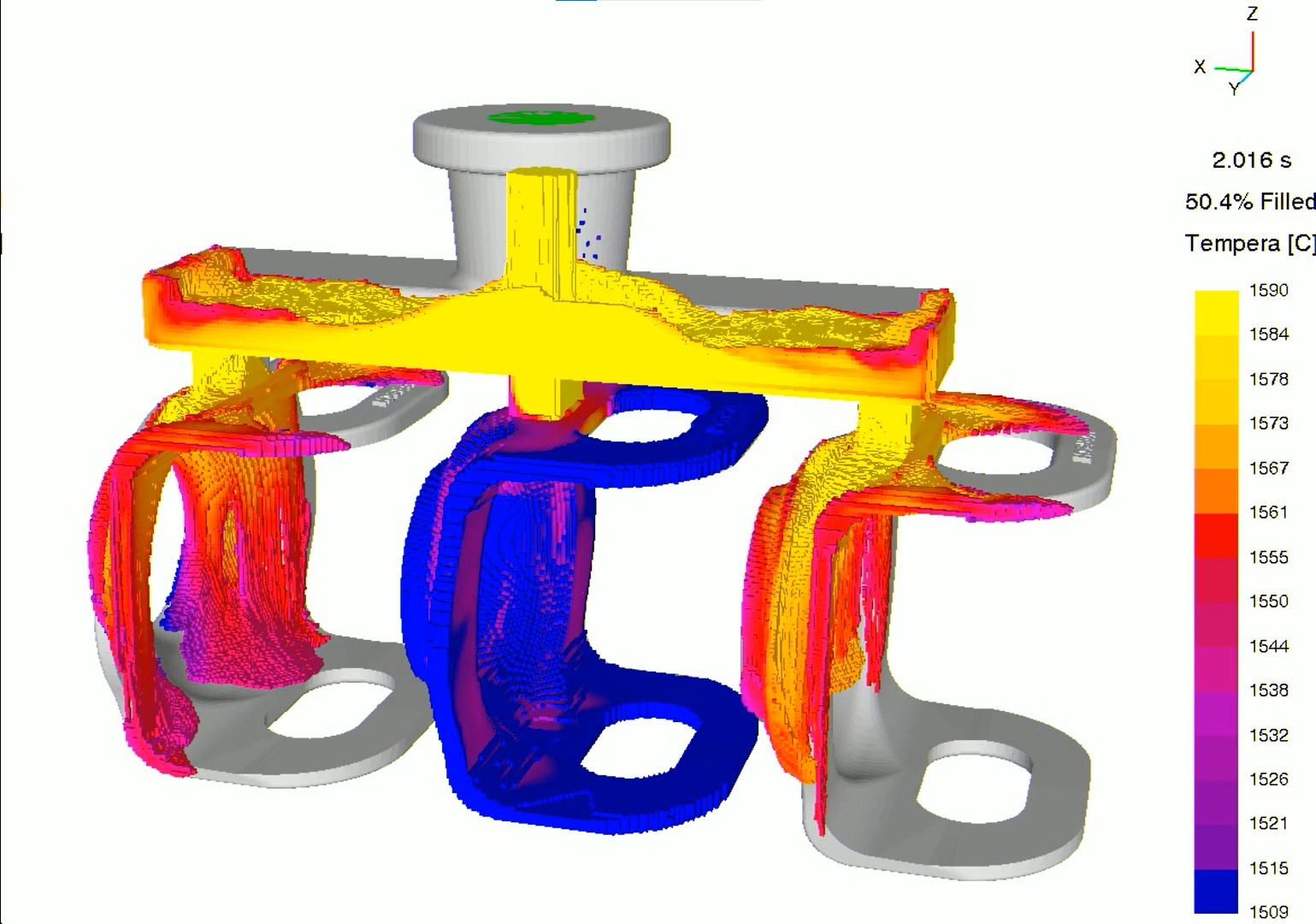

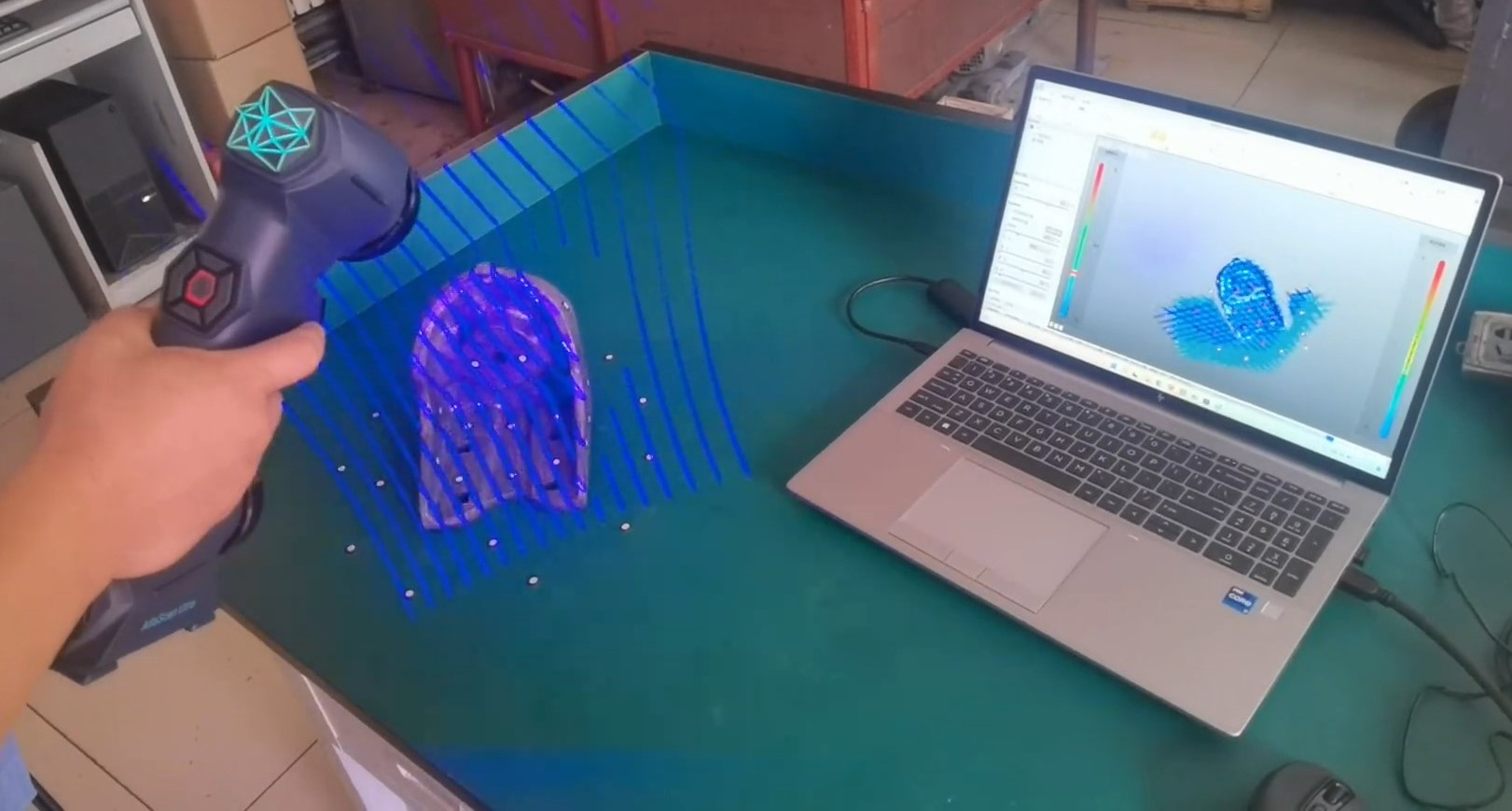

Additionally, the company has integrated digital R&D tools such as Solidcast casting simulation software, Hexagon 3D handheld scanning systems, and bridge-type coordinate measuring machines (CMMs). This forms a full-process quality monitoring network from raw materials to finished products, providing robust technical support and hardware assurance for product innovation and quality control.

English

English