English

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi Pilipino

Pilipino Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська فارسی

فارسی नेपाली

नेपाली ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski Српски

Српски Afrikaans

Afrikaans icelandic

icelandic Беларус

Беларус Hrvatski

Hrvatski Shqiptar

Shqiptar Кыргыз тили

Кыргыз тили Точик

Точик O'zbek

O'zbek հայերեն

հայերեն

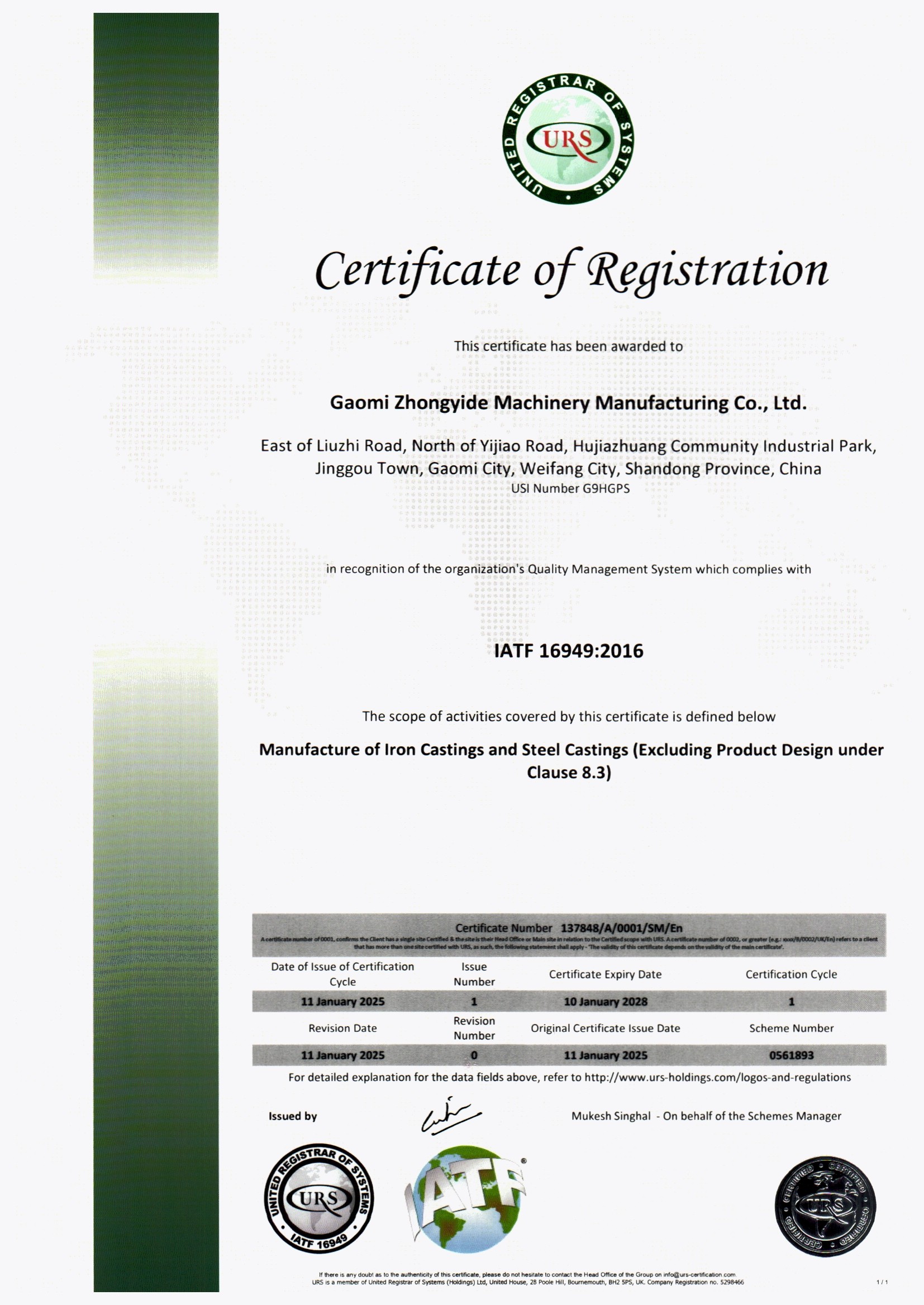

Quality Equipment

The company consistently upholds a scientific and rigorous approach, adhering to standardized measurement protocols, and has continuously introduced a system of internationally advanced R&D and testing equipment.

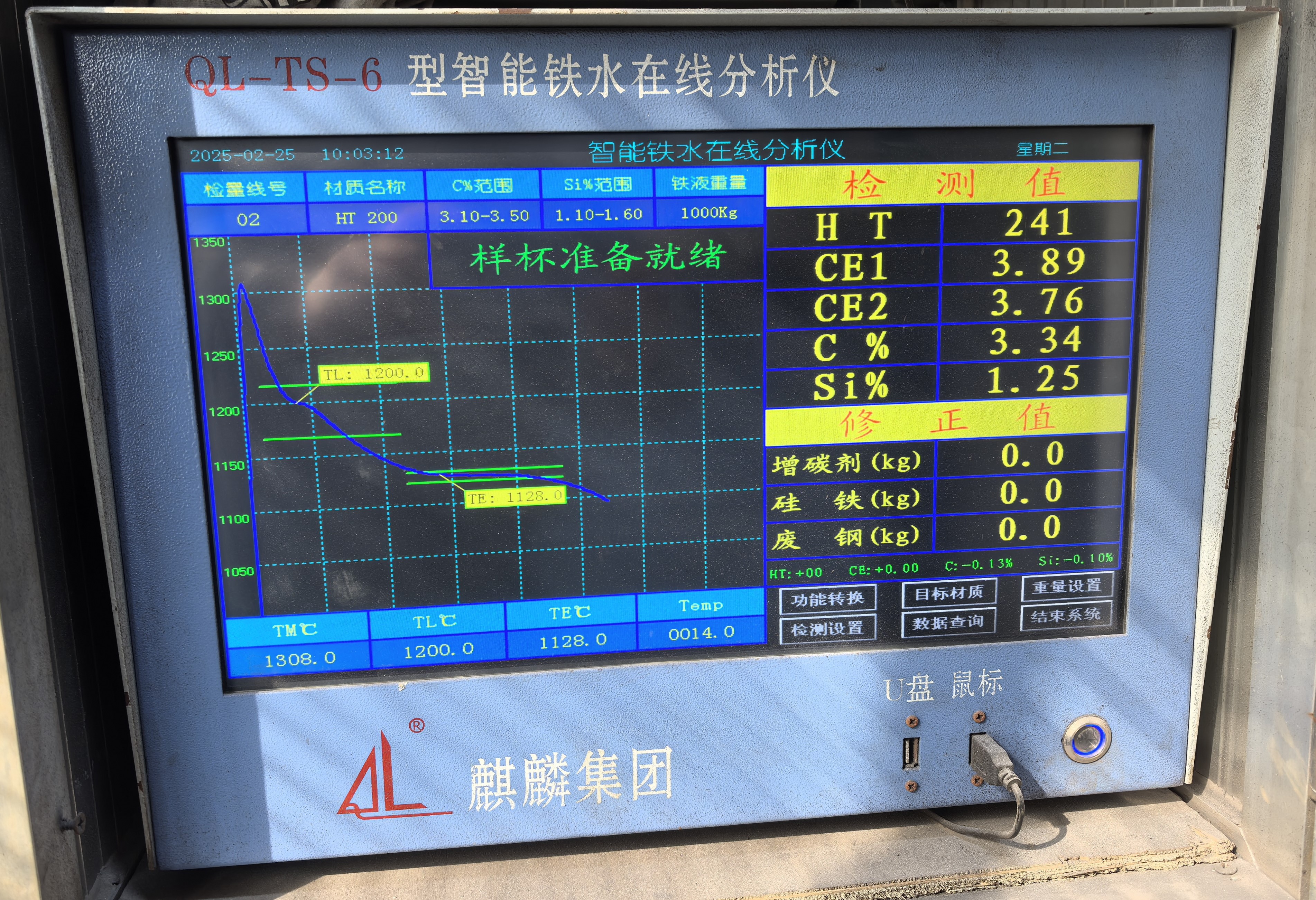

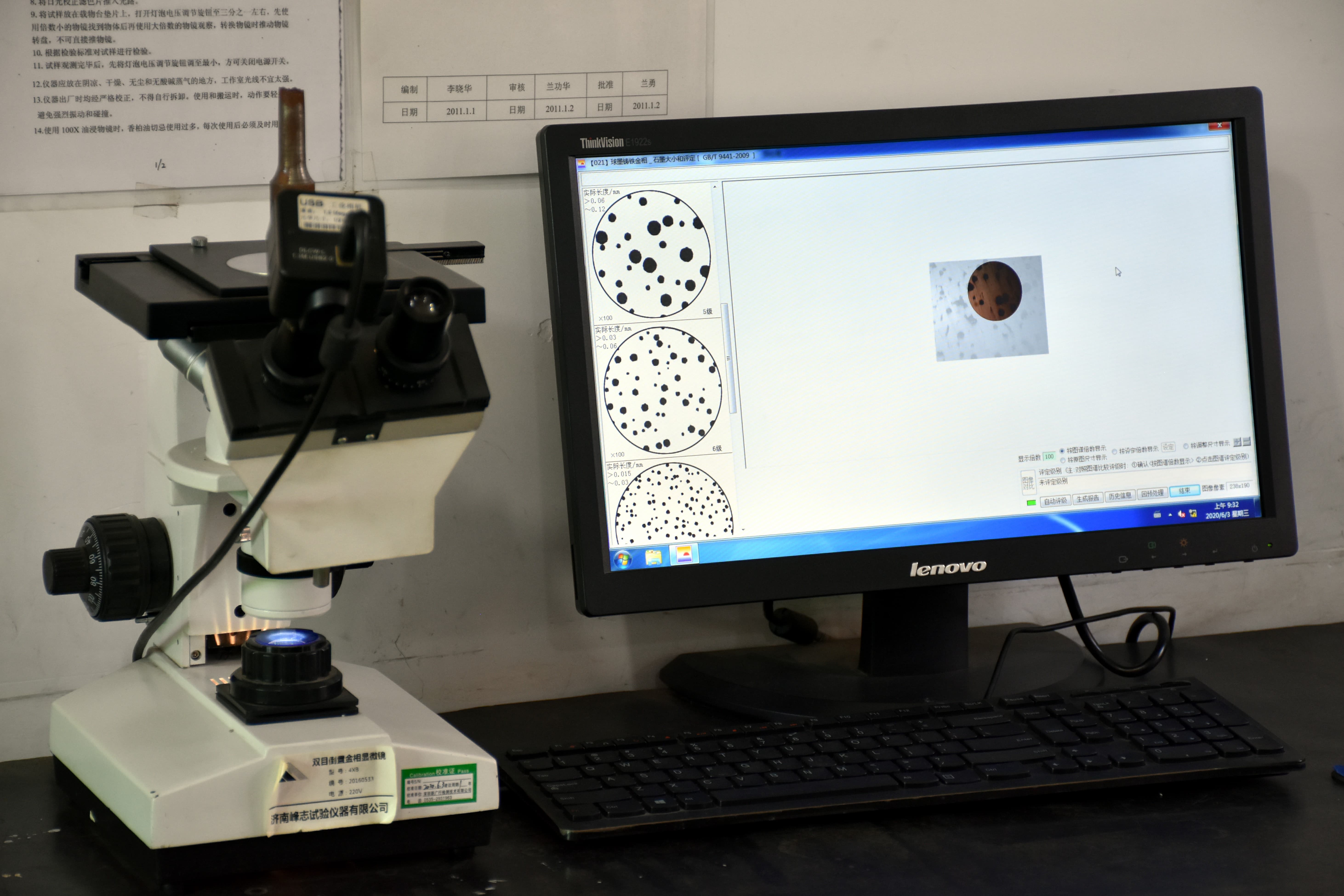

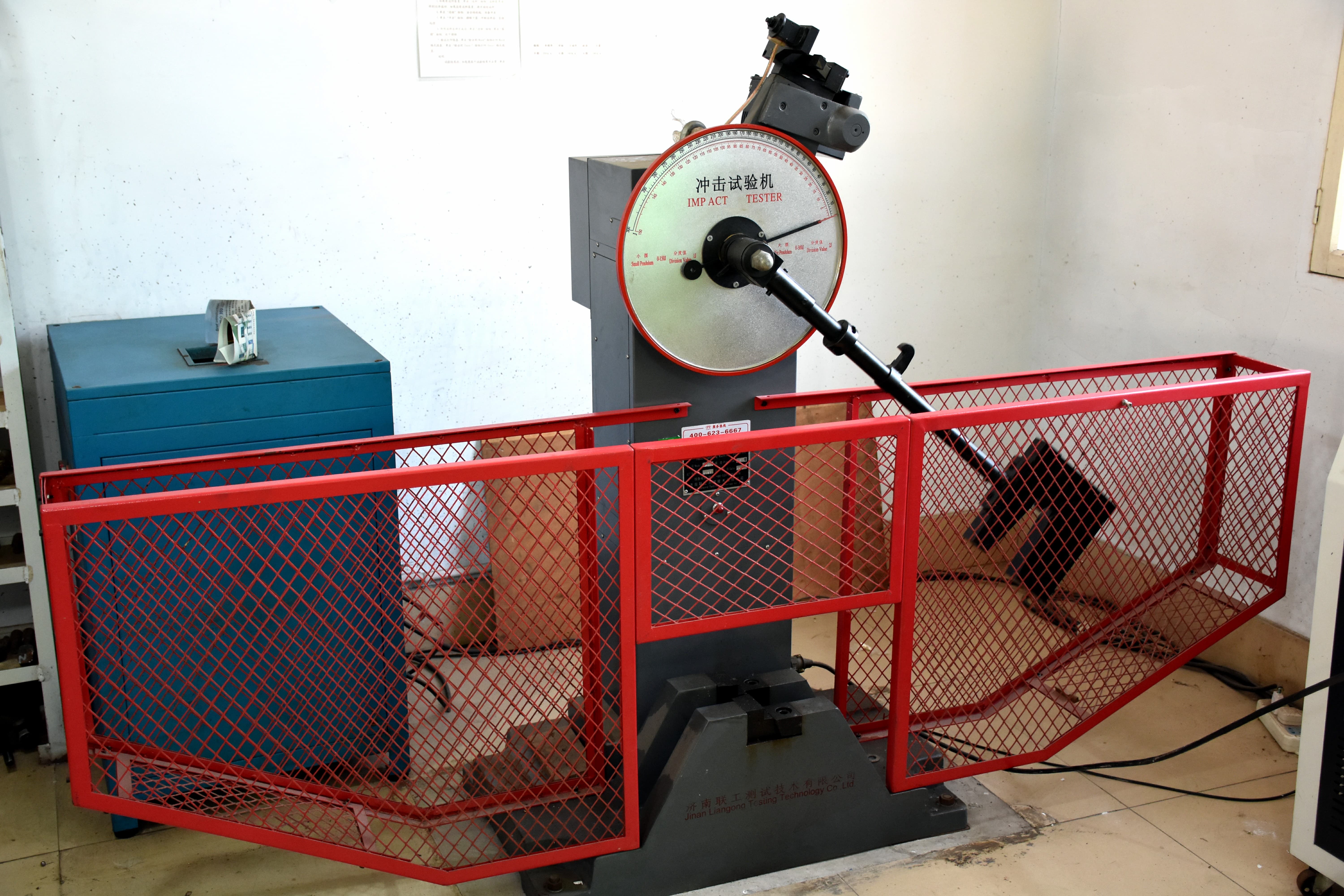

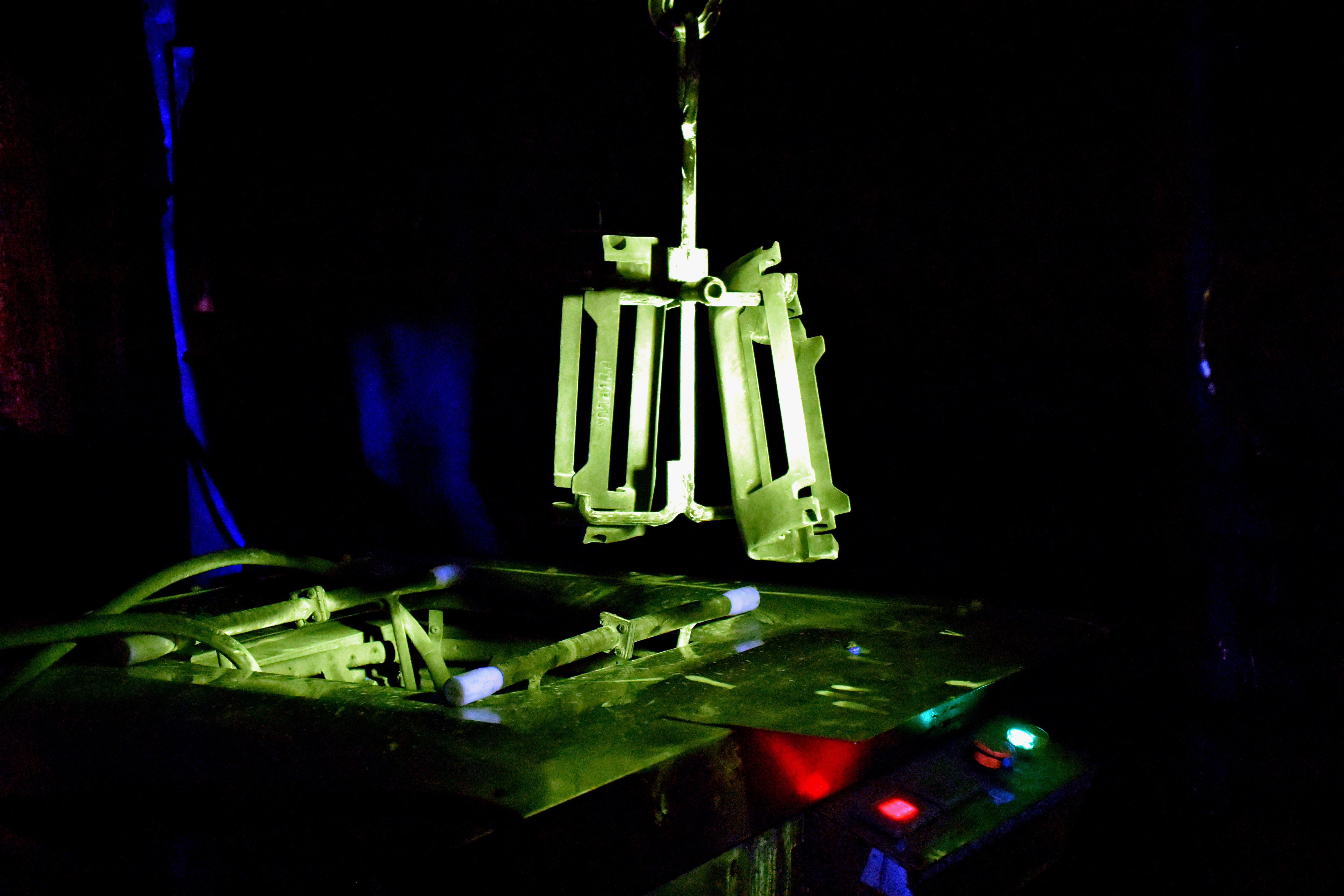

In the field of material analysis, the company is equipped with high-precision optical emission spectrometers, rapid carbon-sulfur analyzers for molten metal testing, and metallographic microscopes. For mechanical property testing, it utilizes computer-controlled electronic universal testing machines, fully automated impact testers, and Brinell/Rockwell hardness testers. In nondestructive testing, the company has established a comprehensive inspection system, including ultrasonic flaw detectors, magnetic particle inspection equipment, and a 450KV X-ray inspection chamber.

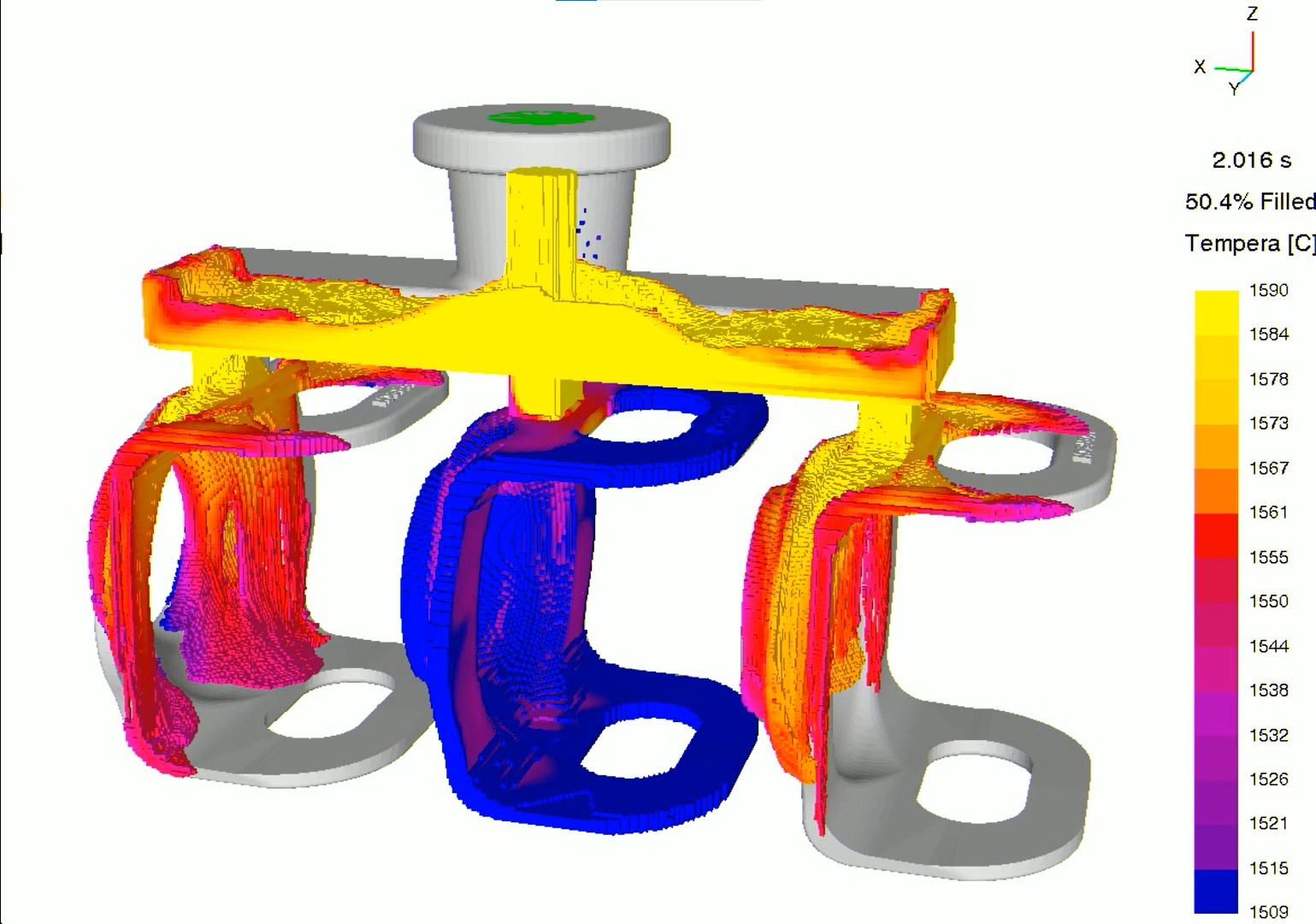

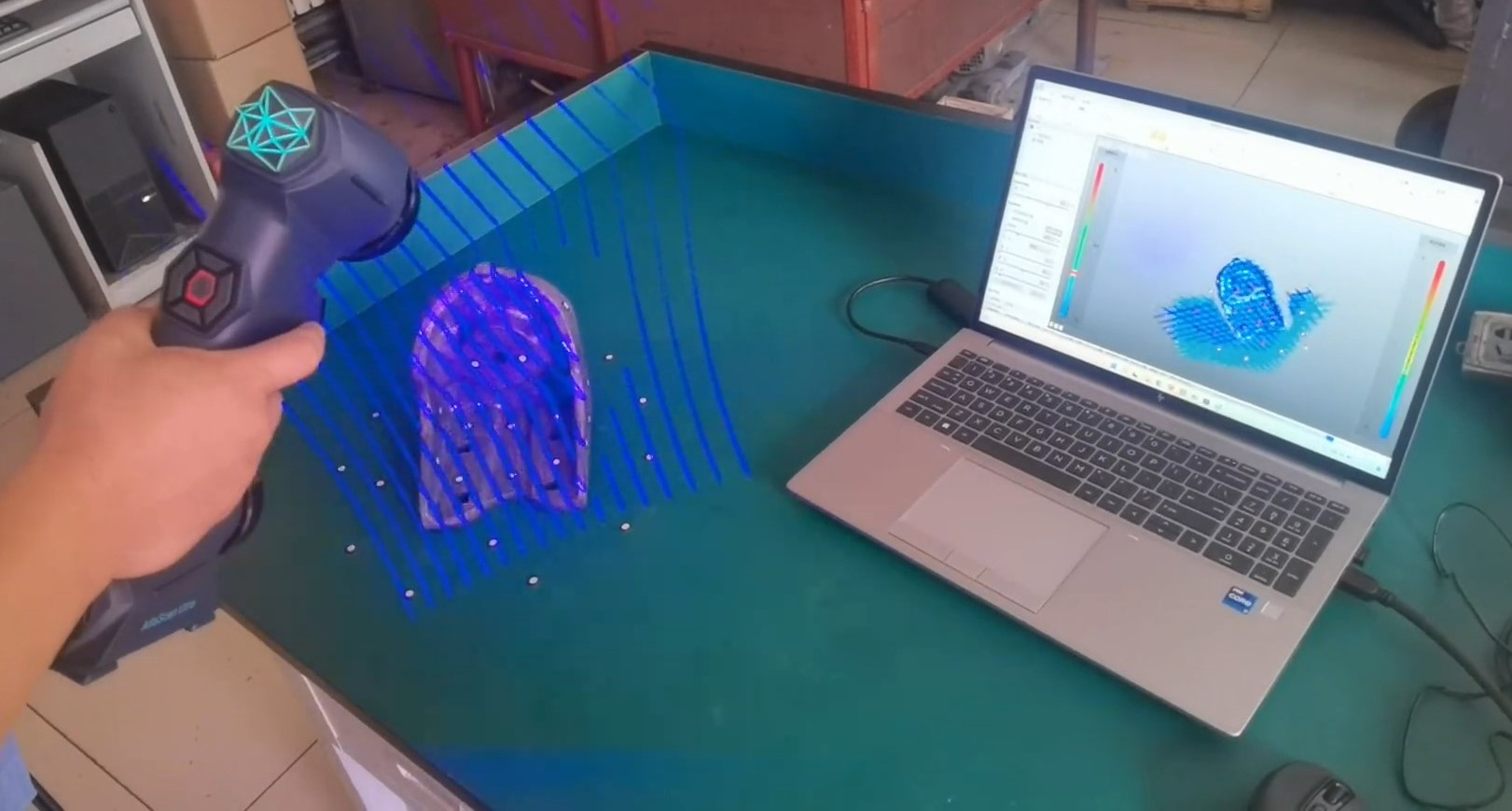

Additionally, the company has integrated digital R&D tools such as Solidcast casting simulation software, Hexagon 3D handheld scanning systems, and bridge-type coordinate measuring machines (CMMs). This forms a full-process quality monitoring network from raw materials to finished products, providing robust technical support and hardware assurance for product innovation and quality control.